+30%

DRY

STRENGTH

Technology DESL®

Ultra-strong paper wiping in dry and wet form

+20%

WET

STRENGTH

+5%

HIGH

ABSORPTION

-20%

LESS

MATERIAL

A new technology for paper wiping, DESL® technology

DESL® heavy duty paper wiping offers a very high-quality product in terms of dry and especially wet strength. It offers 30% more resistance for the same quantity and is also much more economical with 20% less material. DESL® ultra-resistant paper wiping is the result of a combination of the best paper and converting technologies.

A new technology for paper wiping, DESL® technology

DESL® heavy duty paper wiping offers a very high-quality product in terms of dry and especially wet strength. It offers 30% more resistance for the same quantity and is also much more economical with 20% less material. DESL® ultra-resistant paper wiping is the result of a combination of the best paper and converting technologies.

DESL® is an ultra-resistant paper wiping with a high autonomy. It is the result of improved ply bonding, optimal fibre compaction and a unique 40-point embossing pattern that does not break the fibre.

DESL® is a technological solution combined with a strict selection of the best certified long fibres, resulting in rolls with a very high autonomy.

DESL® offers a product that benefits from a new technology similar to TAD. Similar characteristics in terms of wet strength, dry strength, autonomy but above all DESL® paper wiping is much more economical.

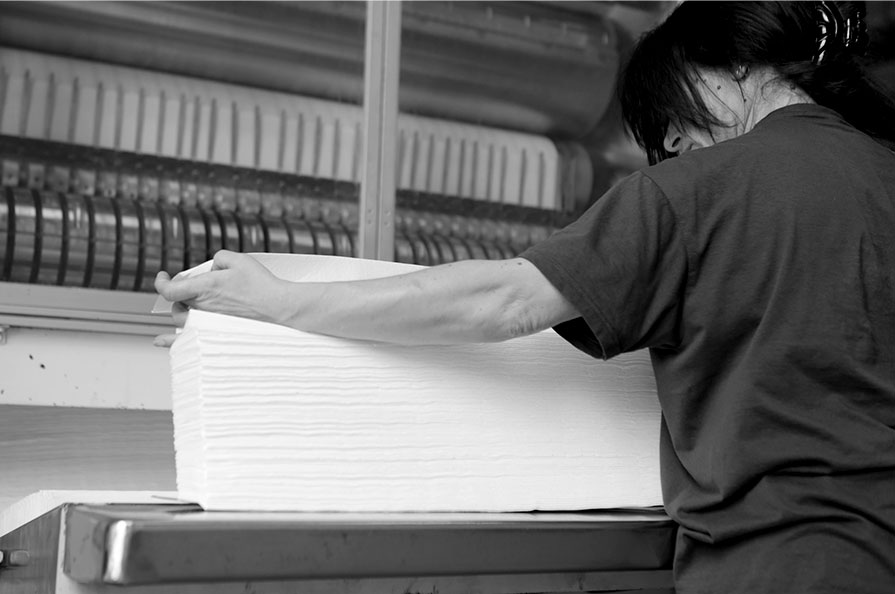

The technology consists of three main manufacturing phases.

First, the fibres undergo an enzymatic treatment. The enzymatic treatment (living active particles) allows for a surface area of adhesion between fibres of almost 100% compared to 60% in a normal process.

The second major step of process optimization is possible thanks to the double press. MP hygiène – Papeterie d’Annonay has a unique double press, last generation, which compared to the single press system, allows a better compaction of the fibres.

The third major step in the performance of DESL® technology is completed by the embossing step. Our embossers have a unique pattern of 40 dots per cm² compared to 20 dots in a standard process. The gluing points are therefore twice as high as the market standard. The design of our embossers retains 100% of the paper’s properties, so it offers optimal wet and dry strength.